In May 2021, Denver met with a major Australian chemical manufacturer to discuss the digital transformation journey in its essential chemical production business unit. The product is a carbon-free ammonia based monofuel suitable for energy storage applications. This fuel is commonly used to make fertilizers, explosives, and as a nutrient in producing antibiotics and yeast.

A digital transformation strategy in a big enterprise needs to be driven by senior leadership. More rapid delivery (through agile, lean methods) is being used to roll out programs with a focus on maximising ROI.

IT and OT are being rolled under a shared umbrella and need to be driven with an innovation culture. Some organisations struggle to manifest an appropriate culture and invest in new people and/or training to promote innovative and disruptive thinking.

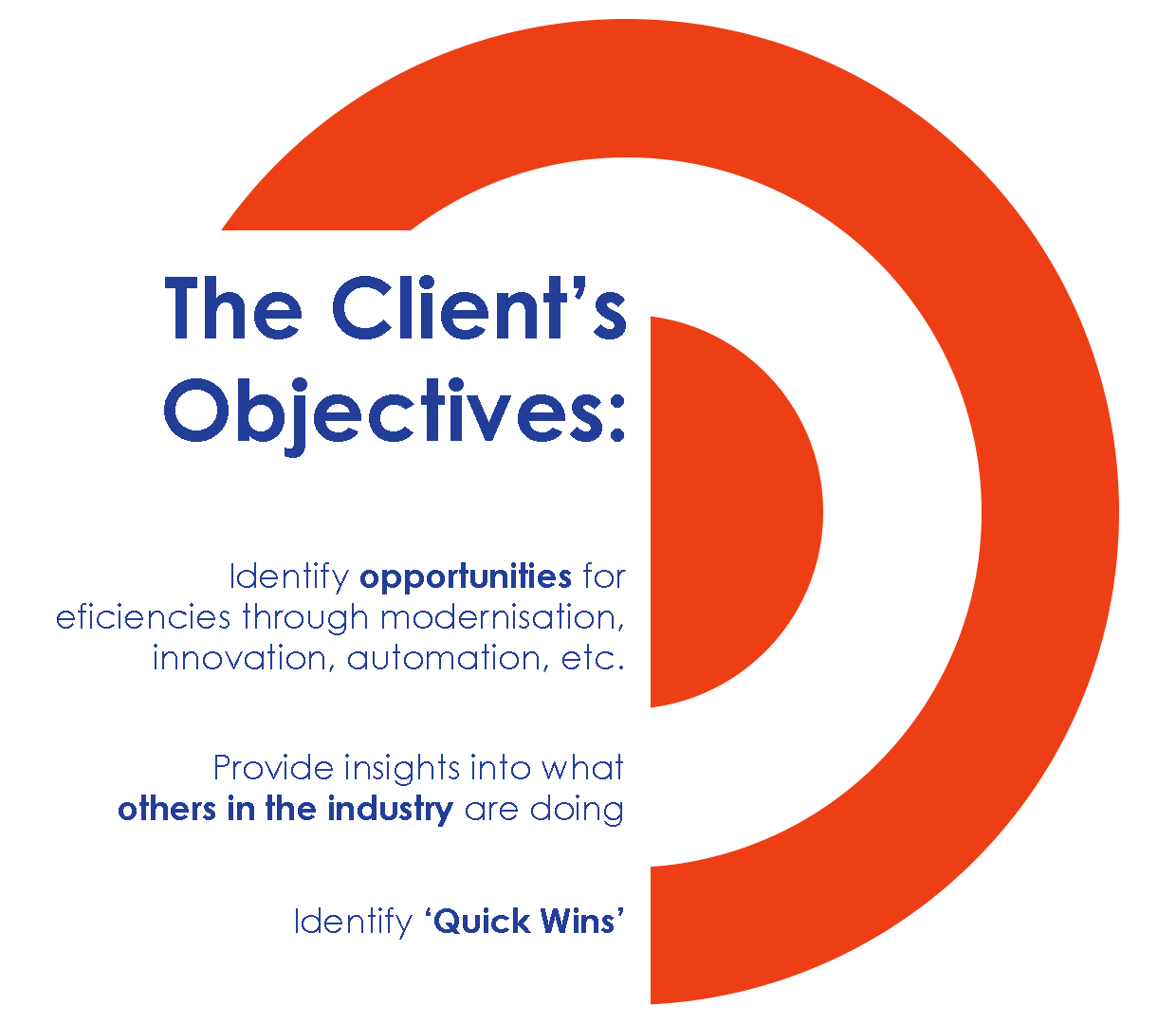

Explore how this culture and digitisation can be leveraged to optimise the operations from Denver’s chemical manufacturer client case study.

The Challenges

- Heavy dependency on people – where a reliance on people means systems and processes are not as good as they could be

- Asset management capability & capacity – challenges with integration & reporting

- Aging workforce – with a transition period expected over the next 5 years

- Business resilience – includes aspects like pandemic resilience

- Efficiencies – increase in business productivity and effectiveness of resource utilisation

The Process Outline

- Pre Read

- Meetings – approx. 30 stakeholders

- In-Review Discussions; Analysis

- Report

- Executive Summary Presentation

In April 2022, Denver met with multiple SMEs across multiple areas to develop a further understanding of the issues and opportunities available.

The Result

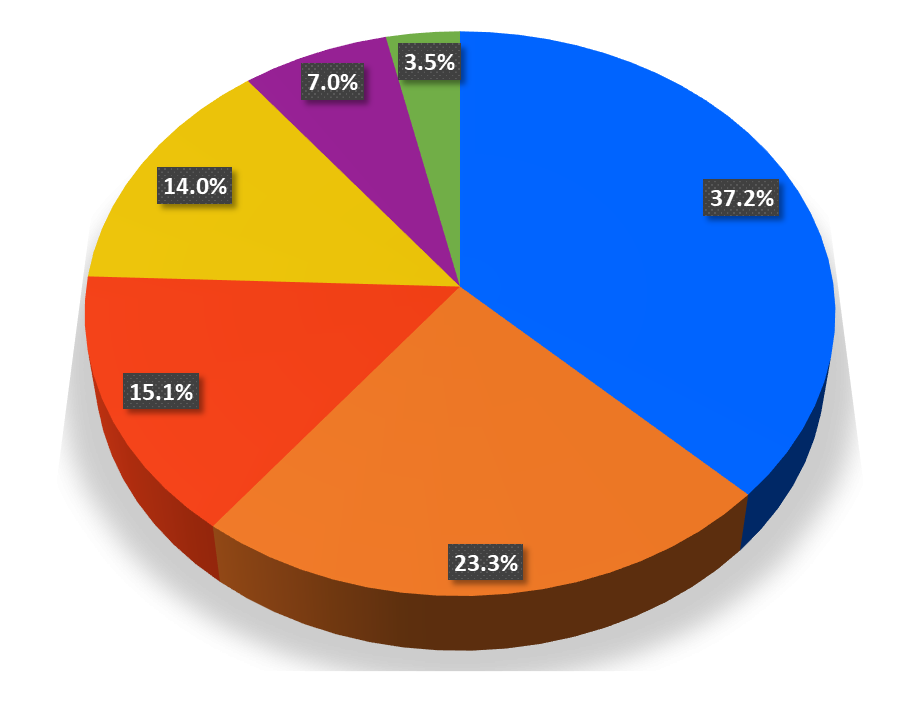

Denver identified approximately 80 opportunity action items in strategy, tactical and operation aspects of the company. All these opportunity items are set under 6 key pillars, which are visualized in the pie chart:

| Defining a strategy and framework for Data Management and Integration | |

| Improve bottom line revenue through commercial agreements and relations | |

| Introduce Enterprise Architecture strategies to enable innovation at a departmental level | |

| Design and define EAM Strategies and Framework | |

| Improve the Capability Maturity to a managed and/or optimised state with a focus on process improvement | |

| Create a strong ESG Value Proposition for higher value creation |

Denver also identifies some action items that are considered priorities and could provide Quick Wins for the company:

Priorities:

| Denver | MacroView Integration |

| Implement a Process Management Framework | |

| Enterprise Architecture for Chemical Manufacturer |

Quick Wins:

| Denver | Product Tracking | |

| Maintenance & Reliability Strategies | |

| Product Counting | |

| Historian & Lab Data Availability |

The Conclusion

The availability of quality data is key. Considered and defined strategies will provide guidance – they don’t need to be exhaustive or overly restricting. Some quick wins at an operational level increases appetite while more complex (and longer duration) initiatives are implemented. Frameworks provide controls and support. Understanding the processes is fundamental to any process improvement and automation at the business unit.

Technology funding from a capex, opex and per person allocation is healthy and not below average. The current asset strategy of ‘sweating assets’ cannot continue moving forward unless strategies are built to support it. The current level of autonomy, leadership and appetite for the AAN business unit allows the chemical manufacturer to drive change in relative isolation.

As a primary provider of revenue to the company, the operations should be a priority client of IT services and recipient of optimisation allocated funding/support. The number of opportunities identified at the business unit (over 80) shows the expansiveness of improvements that can be made as well as the appetite (and ingenuity) of the team members.

Digital Maturity Assessment

What does a digitally mature business look like? Where do you sit on the spectrum? There are many touch points across the pit to port channel that can benefit from innovation.

Read moreCyber-Attacks - 3 Things You Can Do Now to Minimize the Threat.

We hear a lot of cyber attacks like hacking and stolen data.

Read blog